- Servicio de personalización del núcleo

- Cuidado de la salud

- Aparatos e instrumentos electrónicos

- Moldes para suministros maternos e infantiles

- Deportes recreativos

- Arte del mobiliario del hogar

- Accesorios para automóviles

- Transporte y almacenamiento

- Accesorios de iluminación

- Equipo de construcción

- Producto de embalaje

- Educativos y laboratorios

- Ropa Equipaje Accesorios

- Productos de cuidado y limpieza

- Agricultura y silvicultura

- Equipo Mecánico

- Suministros para mascotas

- Batería de cocina

China Tubería y tubo Fabricante, proveedor, fábrica

Ningbo P&M is a factory specializing in injection mold manufacturing and custom plastic product processing, boasting 14 years of rich experience in the field. Over the years, we have catered to a multitude of clients, providing top-notch solutions for their engineering endeavors.

Our expertise extends to a wide array of plastic products and components crafted specifically for engineering projects, each meticulously tailored to meet diverse needs. Whether you require robust, impact-resistant materials or lightweight alternatives, our extensive selection offers solutions for every requirement. From structural elements to functional components, our products are engineered to elevate the performance and efficiency of your projects.

Pipe & Tube play a crucial role in a wide array of engineering projects, serving as essential components in various industries such as construction, manufacturing, transportation, and infrastructure development. These cylindrical structures come in diverse types, each tailored for specific applications based on their material composition, size, shape, and structural characteristics.

Types of Pipe & Tube:

Steel Pipe & Tube: Known for their strength and durability, steel Pipe & Tube are commonly used in construction for applications such as water and gas pipelines, structural support, and in the transportation of fluids and gases.

Copper Pipe & Tube: Copper pipes are valued for their corrosion resistance and thermal conductivity, making them popular choices for plumbing systems, HVAC (heating, ventilation, and air conditioning) installations, and heat exchangers.

PVC (Polyvinyl Chloride) Pipes: PVC pipes are lightweight, cost-effective, and resistant to corrosion, making them ideal for water distribution systems, sewer lines, and electrical conduit installations.

HDPE (High-Density Polyethylene) Pipes: HDPE pipes are known for their flexibility, durability, and resistance to chemicals, making them suitable for applications such as drainage systems, irrigation, and underground utility conduits.

Aluminum Tubes: Aluminum tubes are lightweight, corrosion-resistant, and have excellent thermal conductivity, commonly used in the aerospace industry, automotive applications, and heat exchangers.

Composite Pipes: Composite pipes, made from materials like fiberglass or carbon fiber reinforced polymers, offer high strength-to-weight ratios and corrosion resistance, finding applications in industries such as oil and gas, marine, and chemical processing.

Applications and Importance in Engineering Projects:

Transportation: Pipe & Tube are essential in the transportation sector for vehicle exhaust systems, hydraulic lines, and structural components in aircraft and ships.

Infrastructure: In the construction of buildings, bridges, and roads, Pipe & Tube are used for water supply, sewage systems, HVAC systems, and structural support, ensuring the efficient functioning and longevity of infrastructure projects.

Energy Sector: Pipe & Tube are critical in the energy industry for oil and gas pipelines, steam distribution, and heat transfer systems, facilitating the extraction, transportation, and utilization of energy resources.

Manufacturing: In manufacturing processes, Pipe & Tube are utilized for the conveyance of fluids, gases, and raw materials, as well as in machinery components and equipment fabrication.

Water Management: Pipe & Tube are indispensable in water management projects for irrigation systems, water distribution networks, wastewater treatment, and stormwater drainage, enabling the efficient utilization and conservation of water resources.

In conclusion, the diverse range of Pipe & Tube available in the market cater to the specific needs of various engineering projects, offering solutions that are essential for the construction, transportation, energy, manufacturing, and water management sectors. Their versatility, durability, and functionality make them indispensable components in the modern engineering landscape, contributing significantly to the development and success of a wide range of projects and industries.

Below are the standard processing steps employed in the fabrication of plastic packaging products for the packaging industry:

1. Resin Processing: Raw plastic resins such as polyethylene, polypropylene, PET, etc., undergo drying, blending with additives, and melting in extruders to create a uniform molten polymer.

2. Film Extrusion: The molten plastic is extruded through a flat die to produce a broad sheet or tubing. It is then cooled, stretched, and flattened into a thin plastic film roll.

3. Blow Molding: Molten plastic is injected into a mold cavity, and compressed air is introduced to inflate and shape it into hollow containers like bottles or jars.

4. Injection Molding: Heated plastic is injected into a mold cavity at high pressure to adopt the desired shape. This process is used for manufacturing intricate products such as caps, lids, and closures.

5. Thermoforming: Plastic sheets are heated, molded into shape using matched mold tools, and then trimmed to craft shallow trays and containers.

6. Printing & Decorating: Digital or flexo printing techniques are utilized to apply brand identities and safety information. Laminating is employed to enhance barrier properties.

7. Cutting & Trimming: Plastic rolls or sheets are cut, punched, or notched using tools like scissors, lasers, or dies to create specific shapes.

8. Assembly: Individual components are brought together to form the final packaging product using methods such as adhesives and heat sealing.

9. Finishing: The products undergo a final round of inspection, cleaning, and packaging before being dispatched to end users.

These processes are instrumental in the large-scale production of plastic packaging shapes and configurations with accuracy, consistency, and cost-effectiveness to cater to a variety of product protection and branding requirements.

- View as

Soportes de tubería de plástico

Ningbo P&M se especializa en la fabricación de soportes de tuberías de plástico y moldes de inyección personalizados diseñados para estos componentes, mostrando una experiencia y ventajas excepcionales en este campo especializado. Con una amplia experiencia y un fuerte compromiso con la excelencia, nos hemos posicionado como un proveedor líder de soluciones de soporte de tuberías de plástico de primer nivel. Como fabricante especializado, comprendemos las distintas demandas de la tubería de plástico que soporta el sector. Al emplear tecnologías avanzadas e ingeniería de precisión, desarrollamos moldes de inyección que producen soportes de tubería de plástico impecables. Cada molde sufre una artesanía meticulosa para garantizar dimensiones precisas, acabados suaves y funcionalidad óptima, a......

Leer másEnviar ConsultaAbrazaderas de tubería de plástico

Ningbo P&M se especializa en la fabricación de abrazaderas de tuberías de plástico y moldes de inyección personalizados adaptados a estos componentes, mostrando una experiencia y ventajas excepcionales en este campo especializado. Con una amplia experiencia y un fuerte compromiso con la excelencia, nos hemos posicionado como un proveedor líder de soluciones de abrazaderas de tuberías de plástico de primer nivel. Como fabricante especializado, comprendemos las distintas demandas del sector de abrazaderas de tubería de plástico. Al emplear tecnologías avanzadas e ingeniería de precisión, desarrollamos moldes de inyección que producen abrazaderas de tubería de plástico impecables. Cada molde sufre una artesanía meticulosa para garantizar dimensiones precisas, acabados suaves y funcionalidad ó......

Leer másEnviar ConsultaKits de reparación de tuberías de plástico

Ningbo P&M se especializa en la fabricación de kits de reparación de tuberías de plástico y moldes de inyección personalizados diseñados para estos componentes, mostrando una experiencia y ventajas excepcionales en este campo especializado. Con una amplia experiencia y un fuerte compromiso con la excelencia, nos hemos posicionado como un proveedor líder de soluciones de kit de reparación de tuberías de plástico de primer nivel. Como fabricante especializado, comprendemos las distintas demandas del sector de kits de reparación de tuberías de plástico. Al emplear tecnologías avanzadas e ingeniería de precisión, desarrollamos moldes de inyección que producen kits impecables de reparación de tuberías de plástico. Cada molde sufre una artesanía meticulosa para garantizar dimensiones precisas, a......

Leer másEnviar ConsultaReamers de tuberías de plástico

Ningbo P&M se especializa en la fabricación de escariadores de tuberías de plástico y moldes de inyección personalizados diseñados para estos componentes, mostrando una experiencia y ventajas excepcionales en este campo especializado. Con una amplia experiencia y un fuerte compromiso con la excelencia, nos hemos posicionado como un proveedor líder de soluciones de pipas de plástico de primer nivel. Como fabricante especializado, comprendemos las distintas demandas del sector de redes de tuberías de plástico. Al emplear tecnologías avanzadas e ingeniería de precisión, desarrollamos moldes de inyección que producen escariadores de tubería de plástico impecables. Cada molde sufre una artesanía meticulosa para garantizar dimensiones precisas, acabados suaves y funcionalidad óptima, alineándose......

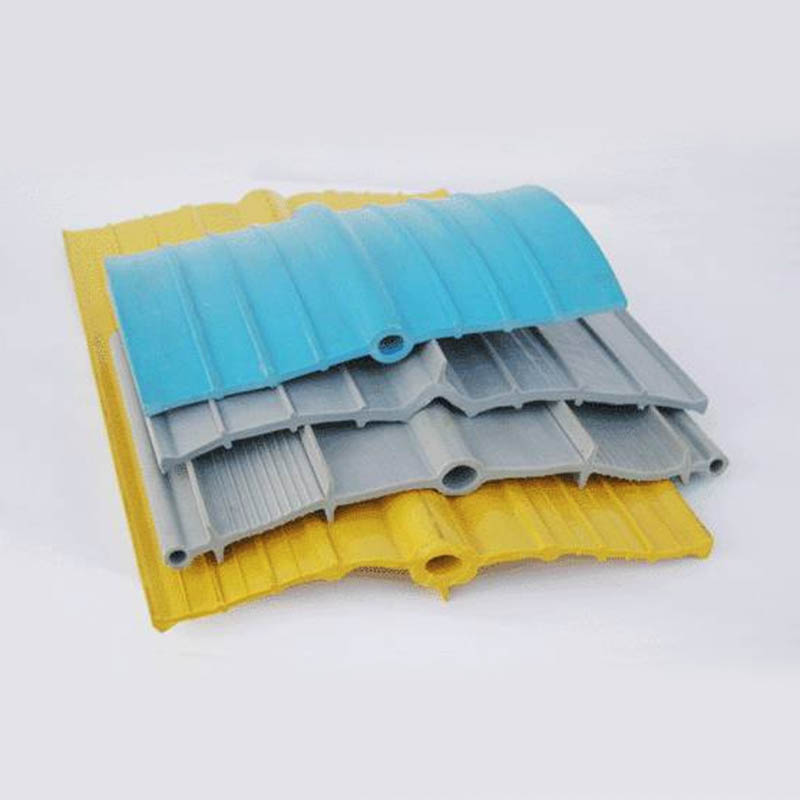

Leer másEnviar ConsultaAislamiento de tubería de plástico

Ningbo P&M se especializa en la fabricación de aislamiento de tuberías de plástico y moldes de inyección personalizados diseñados para estos componentes, mostrando una experiencia y ventajas excepcionales en este campo especializado. Con una amplia experiencia y un fuerte compromiso con la excelencia, nos hemos posicionado como un proveedor líder de soluciones de aislamiento de tuberías de plástico de primer nivel. Como fabricante especializado, comprendemos las distintas demandas del sector de aislamiento de tuberías de plástico. Al emplear tecnologías avanzadas e ingeniería de precisión, desarrollamos moldes de inyección que producen un aislamiento de tubería de plástico impecable. Cada molde sufre una artesanía meticulosa para garantizar dimensiones precisas, acabados suaves y funcional......

Leer másEnviar ConsultaJuntas de expansión de plástico

Ningbo P&M se especializa en la fabricación de articulaciones de expansión de plástico y moldes de inyección personalizados diseñados para estos componentes, mostrando experiencia y ventajas excepcionales en este campo especializado. Con una amplia experiencia y un fuerte compromiso con la excelencia, nos hemos posicionado como un proveedor líder de soluciones de articulación de expansión de plástico de primer nivel. Como fabricante especializado, comprendemos las distintas demandas del sector de juntas de expansión plástica. Al emplear tecnologías avanzadas e ingeniería de precisión, desarrollamos moldes de inyección que producen articulaciones de expansión plástica impecables. Cada molde sufre una artesanía meticulosa para garantizar dimensiones precisas, acabados suaves y funcionalidad ......

Leer másEnviar Consulta