- Servicio de personalización del núcleo

- Cuidado de la salud

- Aparatos e instrumentos electrónicos

- Moldes para suministros maternos e infantiles

- Deportes recreativos

- Arte del mobiliario del hogar

- Accesorios para automóviles

- Transporte y almacenamiento

- Accesorios de iluminación

- Equipo de construcción

- Producto de embalaje

- Educativos y laboratorios

- Ropa Equipaje Accesorios

- Productos de cuidado y limpieza

- Agricultura y silvicultura

- Equipo Mecánico

- Suministros para mascotas

- Batería de cocina

China Nuevos dispositivos médicos Fabricante, proveedor, fábrica

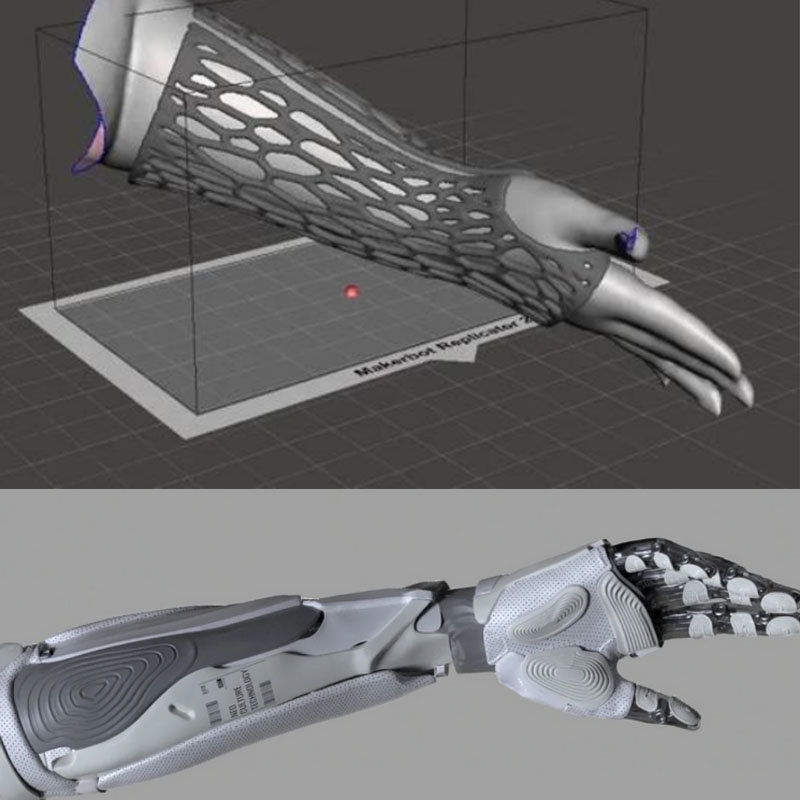

New medical devices mainly include: medical stent, Mechanical arm. The products in this field require high technology and extremely high mold precision, without the slightest deviation, so New Medical Devices has very high requirements for mold materials and production technology.

But we have the technology to complete the production of New Medical Devices. Our factory has national-level technical talents, and we have 42 independent innovation patents.

Mould for New medical devices

We have unique insights in the field of New medical devices. We know what effects customers want, the precautions for matching parts, and how to make molds, so that customers can get the most suitable quotation while ensuring quality.

According to the customer's ideas, we provide a complete solution with high mold precision from mold process analysis, product design optimization, mold design improvement, plastic parts production, etc., to ensure that home health equipment achieves the expected effect in design and use.

The service we provide is a one-stop service, including all processes: 1. Product design-2. 3D drawing production-3. CNC sample testing/3D printing testing-4. Mold making-5. Product production-6. Product packaging-7. Product transportation. We are a complete supply chain that can meet all customer needs.

For molds of New medical devices, the mold material basically requires the two more advanced materials S136 and H13, and the runner of the mold also needs to be designed using a full hot runner, because the technical requirements of New medical devices are very high. Such similar products need to be made using high-precision molds, and the product size error requirements are very small. We are capable of doing it.

The number of mold cavities also needs to be selected according to the customer's production situation. It can be 1 cavity, 2 cavities, 4 cavities, 6 cavities, 8 cavities, 10 cavities, 12 cavities, etc. We can choose the most suitable mold material and number of cavities according to the customer's requirements.

In terms of design, New medical devices products are mainly reflected in functionality. For example, medical stents in the body must not have any obstructive effect on human tissue. We have a certain amount of research on human medicine and know what kind of product appearance design can meet the relevant requirements and what kind of product design can better realize the function of the product.

In terms of materials, New medical devices mainly reflect the safety and durability of the product. Such similar products are basically made of special materials to ensure safety during use and not cause rejection reactions, etc.

New medical devices mold description

Mold frame: 45 steel

Model: S136/H13

Cavity: Customized

Runner: Hot runner

Injection system: Ejector with automatic mechanism

Delivery time: 25 days

Parts material:PP

- View as

Moldeo de stent médico

Ningbo (P&M) Plastic Metal Products Co., Ltd. tiene 17 años de tecnología de fabricación de moho y puede personalizar el moldeo de stent médico. Brindamos servicios profesionales de molde de stent médico personalizados, y somos un fabricante profesional de moho de stent médico. Tenemos suficiente experiencia en la selección de materias primas y materiales de moho. En el proceso de personalización de moldes de stent médico, nuestra fábrica puede proporcionar un servicio único. Tenemos capacidades de diseño y producción relacionadas con stents médicos, tales como: diseño CAD, fabricación de moho, moldeo por inyección, producción de productos plásticos, ensamblaje y otras tecnologías.

Leer másEnviar ConsultaMoldeo de brazo mecánico

Ningbo (P&M) Plastic Metal Products Co., Ltd. tiene 17 años de tecnología de fabricación de moho y puede personalizar los moldes de brazos mecánicos. Brindamos servicios profesionales de moldeo de brazo mecánico personalizados, y somos un fabricante profesional de moho de brazo mecánico. Tenemos suficiente experiencia en la selección de materias primas y materiales de moho. En el proceso de personalización de moldes de brazos mecánicos, nuestra fábrica puede proporcionar un servicio único. Tenemos capacidades de diseño y producción relacionadas con los brazos mecánicos, como: diseño CAD, fabricación de moho, moldeo por inyección, producción de productos plásticos, ensamblaje y otras tecnologías.

Leer másEnviar Consulta